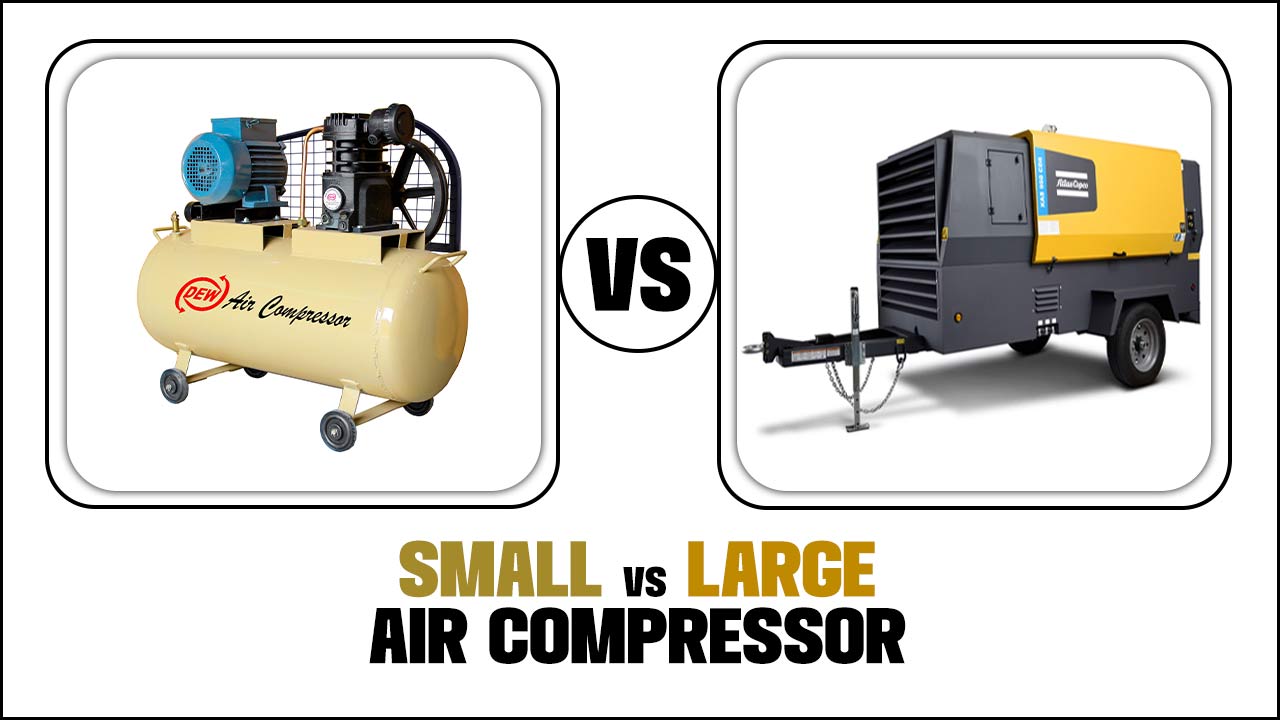

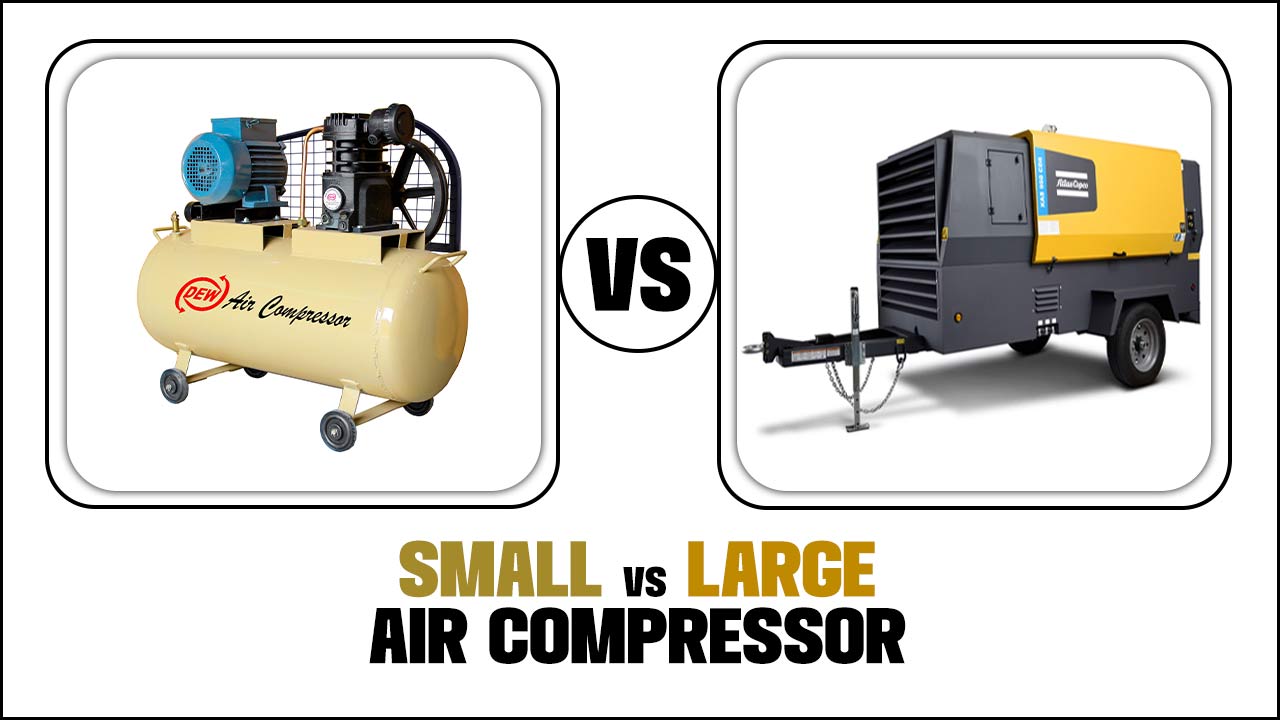

Air compressors are an essential part of industrial and commercial operations, and the choice of small or large air compressor will depend on the application.

Small air compressors are typically used for light-duty applications, such as powering air tools, inflating tires, or providing air pressure to a spray gun. On the other hand, large air compressors are used for more heavy-duty applications, such as powering pneumatic tools, powering air-operated equipment, and providing air pressure for larger spray guns.

In this article, we will discuss the differences between small and large air compressors and help you decide which one is best for your needs.

Small Vs. Large Air Compressors

When it comes to choosing an air compressor for your needs, it is important to understand the differences between a small air compressor and a large air compressor. Small air compressors are typically used for small, infrequent tasks such as inflating a tire or running a nail gun.

On the other hand, large air compressors are typically used for larger, more frequent tasks such as powering a pneumatic tool or powering a spray gun. Both small and large air compressors have their own advantages and disadvantages, and it is important to consider these when deciding which type of compressor is best for you. In this article, we will discuss the differences between small and large air compressors, and help you decide which is best for your needs.

Overall Comparison

When it comes to air compressors, the size of the device is an important factor to consider when making a purchase. Smaller compressors tend to be cheaper than large compressors and are ideal for light-duty jobs, such as inflating tires and powering airbrushes. On the other hand, larger compressors are more powerful and can handle more intensive tasks, like powering air tools.

In addition, larger compressors usually have more features, such as pressure gauges and air filters, and they are more durable. Ultimately, the choice between a small or large compressor depends on the intended use, budget, and available space.

Price

When it comes to price, small air compressors tend to be more affordable than larger ones. Smaller air compressors typically cost anywhere from $100 to $500, while larger air compressors can cost anywhere from $500 to over a thousand dollars.

However, the price of a large air compressor can be worth it if you need more power for larger projects. They are also more durable and require less maintenance, meaning you can get more use out of them over time. Ultimately, the size of the air compressor you need and your budget will determine which type of compressor is best for you.

Size

Size is an important factor to consider when choosing an air compressor. Smaller air compressors are more compact, making them ideal for light-duty jobs that require portability. They are also less expensive than larger models and generate less noise. On the other hand, large air compressors are more powerful and can handle more demanding tasks.

While they are more expensive and bulky, they are great for industrial or commercial applications. The size of the air compressor you need will depend on your specific needs. For a small home project, a small air compressor might be the best choice. If you require something more powerful, a large air compressor is the better option.

Power

When it comes to air compressors, power is the main factor in deciding which type is best for you. Small air compressors are designed for basic home projects and small automotive needs, and usually have a power rating of 1-3 horsepower. On the other hand, large air compressors are better suited for heavy-duty work, and have a power rating of 5-20 horsepower.

If you require a powerful air compressor for commercial or industrial use, then a large air compressor is the way to go. However, if you only need to inflate a bike tire or clean a small area, then a small air compressor will do the job.

Maintenance

When it comes to air compressors, one of the most important aspects to consider is the maintenance required. Small air compressors typically have fewer components and require less maintenance overall. They are less likely to break down, and repairs, if necessary, can be completed quickly and easily.

On the other hand, large air compressors have more components and require more regular maintenance. You will need to invest time in checking and cleaning the filters, replacing parts, and more. This can be more costly and time-consuming than with smaller compressors. Additionally, large compressors may require specialized tools or trained personnel to carry out maintenance tasks.

Pros And Cons

When it comes to air compressors, choosing between a small or large model is a big decision. Each have their own advantages and disadvantages. Small air compressors are usually less expensive and are more portable, making them ideal for a wide range of projects that don’t require a large amount of air pressure.

On the other hand, large air compressors provide a considerable amount of air pressure and can handle more powerful and longer-lasting jobs. However, they are more expensive and less portable than small compressors. Both types of compressors offer their own unique benefits, and the decision depends on a variety of factors, such as the type of project you are working on and your budget.

Small compressors are perfect for smaller projects, such as inflating tires and powering small pneumatic tools, while large compressors are suitable for bigger projects, such as powering large machinery and powering large pneumatic tools.

Small Air Compressor

Small air compressors are a great choice for anyone who needs compressed air on a smaller scale. They typically weigh less than large air compressors, making them easy to transport and store. They are also generally quieter and more affordable than their larger counterparts.

Small air compressors are perfect for tasks such as powering spray guns, airbrushes, and small pneumatic tools. They also come in a variety of sizes and configurations, allowing you to find the perfect compressor for your specific needs.

Large Air Compressor

Large air compressors are ideal for industrial or commercial-scale applications, where large volumes of air must be supplied on a regular basis. They are usually powered by an electric motor or a diesel engine, and have a bigger tank capacity than small compressors. Large air compressors can usually generate higher amounts of pressure, and they are able to supply the air for long periods of time.

They are typically used in construction sites, factories, and other places that require large amounts of air. These compressors are also used to power air tools for heavy-duty tasks like sandblasting or painting. They are more expensive than small air compressors, but provide more air over a longer period of time.

Applications

Air compressors are used in a variety of applications. Small air compressors are useful for tasks that require a low volume of air, such as inflating a tire or powering a nail gun. Large air compressors, on the other hand, are used for tasks that require a higher volume of air, such as powering a jackhammer or running a spray gun.

The power of the air compressor is determined by the size of the tank, and a larger tank is needed for more demanding tasks. For instance, sandblasting requires a large air compressor in order to provide enough power to properly remove surface material. Additionally, large air compressors are usually used for industrial applications, such as powering industrial machinery or tools. Smaller air compressors are more suitable for DIY projects and light-duty tasks.

Home Use

When it comes to air compressors for home use, the two main categories are small and large. Small air compressors are ideal for small tasks such as inflating tires or powering airbrushes. They are usually lightweight and portable and can be stored easily. Large air compressors, on the other hand, are better suited for larger tasks such as powering nail guns and spray guns.

They are usually stationary and require more storage space. Both types of air compressors have their advantages and disadvantages, and which one you choose will depend on your specific needs. Small air compressors are more affordable and require less maintenance, but they are limited in power.

Large air compressors, while more expensive, are more powerful and can handle larger jobs. Ultimately, the best air compressor for you will depend on your budget and the tasks you plan to use it for.

Commercial Use

When it comes to commercial use, the choice between a small air compressor and a large air compressor depends on the specific needs of the job. Small air compressors are suitable for light-duty tasks, such as painting, automotive repair, and powering pneumatic tools. While they may be able to handle some more demanding tasks, their limited power and capacity can limit their ability to do larger jobs.

On the other hand, large air compressors are designed to handle more intense jobs, such as sanding, grinding, and heavy industrial use. They are more powerful and have larger tanks, allowing them to work for longer periods of time without needing to be refilled. However, they are more expensive and require more space to operate.

Industrial Use

When it comes to industrial use, the choice between a small air compressor and a large air compressor depends on the task at hand. Small air compressors are ideal for lighter duties, such as powering pneumatic tools or inflating tires.

They are usually more portable, making them easy to move from place to place if needed. Large air compressors, on the other hand, are better suited for more demanding tasks such as painting or sandblasting.

They also tend to be less portable due to their size and weight. They require a larger motor and are more expensive to purchase and maintain. Both types of air compressors have their advantages and drawbacks, and the decision ultimately depends on the specific job requirements.

Conclusion

When it comes to air compressors, there is no one-size-fits-all solution. Small air compressors are ideal for light-duty tasks such as inflating tires and running small pneumatic tools, while larger air compressors are better suited for more demanding tasks such as powering multiple tools at once or running larger equipment. Ultimately, the size of air compressor you need depends on the type of job you are doing and how much power you require.

FAQ’s

1.What Are The Advantages And Disadvantages Of A Small Air Compressor Compared To A Large Air Compressor?

Ans: The main advantages of a small air compressor compared to a large one are that they are typically more affordable, easier to transport, and require less storage space. On the other hand, the main disadvantage of a small air compressor is that it is less powerful and therefore not suitable for large-scale applications.

2.How Much Power Does A Small Air Compressor Typically Require?

Ans: A small air compressor typically requires 1-2 horsepower of power. The power required usually depends on the size of the compressor and the type of work it is required for. Most small air compressors have a capacity of up to 6-7 CFM, which is enough for most small tasks like inflating tires or running a nail gun. The power requirements may vary depending on the specific model.

3.What Types Of Applications Are Best Suited To A Large Air Compressor?

Ans: Applications that require high pressure and high flow, such as spraying, sandblasting, and power tool operation, are best suited to a large air compressor. Compressors with larger tanks are more suitable for heavy-duty applications that need a great deal of air, such as powering a jackhammer or grinding tool.

Industrial applications such as waterjet cutting and operating air-driven tools also require large air compressors. Lastly, large air compressors are best for powering pneumatic tools such as paint sprayers and staplers.

4.How Much Storage Space Do Large Air Compressors Typically Require?

Ans: Large air compressors typically require a significant amount of storage space. This is because they are typically very large and bulky pieces of machinery. The size and capacity of the air compressor will determine how much storage space is needed. As a general rule, it is best to plan on needing at least 20 square feet of storage space for any large air compressor.

5.What Safety Considerations Should Be Taken Into Account When Using A Small Air Compressor?

Ans: When using a small air compressor, it is important to take safety precautions such as wearing protective eyewear, gloves, and clothing. There should also be adequate ventilation to ensure that combustible fumes do not accumulate. Additionally, the hose should be checked for any signs of wear and tear before each use. Finally, the pressure should be monitored to ensure it does not exceed the compressor’s maximum capacity.