If you are a DIY enthusiast or a professional mechanic, having an air compressor can be a valuable tool in your arsenal. But how to Set Up Your Air compressor properly? Firstly, choose a location for your air compressor; a dry and well-ventilated area is ideal.

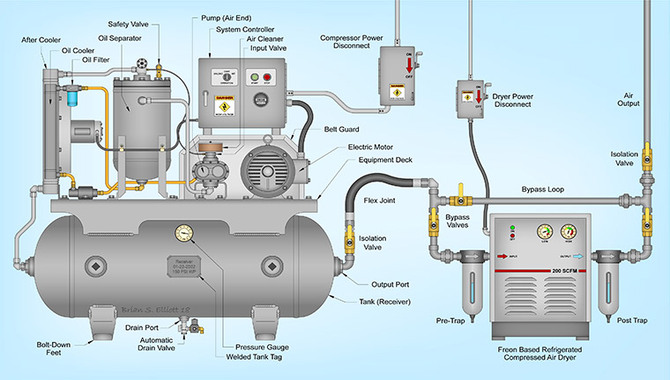

Next, ensure that the compressor is placed on a flat, stable surface and that it is plugged into a grounded electrical outlet. Before turning it on, ensure the tank is empty, and the drain valve is closed. Connect the air hose to the compressor’s outlet valve using a quick-connect coupling. Correct fittings and couplings are essential to avoid leaks and pressure drops.

If you are unsure about the type of fitting you need, consult the manufacturer’s manual or a professional. Once the air hose is connected, adjust the regulator knob to set the pressure at the desired level. Monitoring the pressure gauge regularly is essential to ensure the compressor is running correctly.

What Is An Air Compressor?

An air compressor is a machine that converts power from an electric motor, diesel or gasoline engine, or other sources into potential energy stored in compressed air. Compressed air is used for various applications such as filling tires, powering pneumatic tools, and operating industrial machinery.

Air compressors come in different sizes and capacities, depending on the intended use. The compressor draws ambient air through an intake valve and compresses it into a storage tank, where the compressed air is held until needed. The pressure level of the compressed air can be adjusted using a pressure regulator valve and monitored with a pressure gauge.

How To Set Up Your Air Compressor In 10 Easy Ways

The setup of your air compressor is crucial for its optimal functioning and longevity. The proper setup ensures that the compressor runs efficiently, reduces wear and tear on its components, and extends its lifespan. It’s essential to know how to set up your air compressor.

The compressor should be placed on a level surface away from direct sunlight, heat sources, and moisture. It should be situated in a well-ventilated area to prevent overheating. These should be compatible with your compressor’s specifications and rated for your intended applications’ pressure and temperature requirements.

- Find a level surface to set up your air compressor.

- Make sure your compressor is placed near an electrical outlet.

- Attach the air filter to the intake valve.

- Connect the pressure regulator to the outlet valve.

- Attach the air hose to the regulator and tighten the clamp.

- Connect any other air tools or accessories to the hose.

- Turn on the compressor and let it run for a few minutes to build up pressure.

- Adjust the pressure regulator to the desired level.

- Use the air tools as needed, but be sure to follow the manufacturer’s instructions.

- When finished, turn off the compressor and release pressure from the hose.

How To Use An Air Compressor Safely

When using an air compressor, it is crucial to prioritize personal safety. Operating an air compressor without proper precautions can lead to accidents, such as flying debris, sudden release of compressed air, or even explosions. Following safety guidelines helps protect yourself and others from potential harm. Here are the steps for using an air compressor.

1. Choose A Location

Choosing a location can be daunting, especially regarding big life decisions like buying a house or starting a business. However, taking the time to research and consider your options can greatly improve your overall satisfaction and success. When choosing a location, there are several factors to consider.

First, think about your needs and priorities. Do you value a bustling city atmosphere or a peaceful rural setting? Do you need to be close to certain amenities like schools, hospitals, or public transportation? Once you’ve identified your top priorities, start exploring different neighborhoods and cities that fit the bill.

Look at factors like housing prices, crime rates, and job opportunities to get a sense of the overall quality of life in each area. You may also want to consider the climate, proximity to family and friends and accessibility to outdoor activities. Ultimately, the key is to find a location that meets your needs and feels like home.

2. Check The Oil Level

One of the most important things you can do to keep your car running smoothly is to check the oil level regularly. Oil is the lifeblood of your engine, lubricating the moving parts and keeping everything running smoothly. Without enough oil, your engine can seize up and cause serious damage.

To check the oil level, ensure your car is parked on a level surface, and the engine is turned off. Open the hood and locate the dipstick, usually marked in bright colors for easy identification. Pull it out and wipe it clean with a rag or paper towel. Then reinsert the dipstick all the way back in and pull it out again.

The oil level should be between the two marks on the end of the dipstick. If it’s low, add more oil until it reaches the upper mark. Be sure to use the type of oil recommended by your car’s manufacturer, and don’t overfill the engine.

3. Install An Intake Filter

If you want to improve your home’s air quality, installing an intake filter is one simple yet effective step. An intake filter helps to remove harmful particles and allergens from the air before they enter your home’s ventilation system. This can be especially beneficial for those who suffer from allergies or respiratory issues.

Installing an intake filter is a relatively easy process for most homeowners. First, you’ll need to determine the size of your current intake opening to find the appropriate filter size. Once you have the appropriate filter, you can remove the old one and replace it with the new filter. Following the manufacturer’s instructions is important as ensuring the filter is installed securely.

Regularly changing the filter is also important to ensure it effectively removes particles from the air. Depending on the type of filter you choose, you may need to replace it every few months or once a year.

4. Connect The Air Hose

The mechanic instructed the driver to connect the air hose to the truck’s brake system before he could perform the necessary repairs. The driver groaned at the prospect of having to manoeuvre the bulky hose in the cramped space under the trailer. He struggled to find the right angle and position to attach it securely, his frustration growing by the minute.

The mechanic watched patiently, offering advice and guidance when needed until the driver finally managed to snap the hose into place with a satisfying click. They both breathed a sigh of relief, knowing the brakes were now fully functional and safe.

The mechanic then inspected the rest of the truck, making notes and recommendations for further maintenance. The driver listened attentively, grateful for the expert’s expertise and attention to detail. He knew keeping his vehicle in top condition was crucial for his job and safety.

5. Connect The Pressure Switch

In order to ensure the proper functioning of a pump system, it is crucial to connect the pressure switch correctly. The pressure switch is responsible for monitoring the pressure levels within the system and activating the pump when necessary.

To connect the pressure switch, first, it is important to locate the switch itself and the wiring diagram for the system. Once you identify both, wire the switch to the power source and the pump motor. It is important to ensure the wiring is correct and secure to prevent electrical hazards. After the wiring is complete, the pressure switch you can calibrate to the desired pressure settings.

This is done by adjusting the switch’s pressure setting screws to the desired levels. It is important to note that the calibration should be done carefully, as incorrect settings can lead to system malfunction or damage. Once the pressure switch is connected and calibrated, it can monitor the pressure levels and activate the pump when necessary.

6. Adjust The Regulator Valve:

When working with gas appliances, it’s important to know how to adjust the regulator valve. The regulator valve controls the gas pressure in the appliance and ensures that it’s safe. If the pressure is too high, it can cause damage to the appliance or even be dangerous.

To adjust the regulator valve, you’ll first need to locate it. It’s usually located near the gas inlet and will have a knob or screw that you can turn to adjust the pressure. Before making any adjustments, make sure to turn off the gas supply and wait for the appliance to cool down.

Once you’ve located the regulator valve and turned off the gas supply, you can start adjusting the pressure. Use a pressure gauge to determine the current pressure and adjust the valve accordingly. It’s important to make small adjustments and test the pressure after each one to ensure you don’t make the pressure too high or too low.

7. Plug In The Power Cord:

Before using any electronic device, it is important to plug in the power cord. This simple step ensures that the device has a steady source of power and can function properly. Without the power cord, the device will not be able to turn on and will not be able to perform its intended functions.

The first step in getting started with a computer, a television, or a gaming console is to plug in the power cord. Ensure that you securely plug the power cord into both the device and the power outlet to avoid any issues. Interruptions in power flow.

Additionally, it is important to use the correct power cord for the specific device, as using a different cord could cause damage to the device or even create a safety hazard. Taking a moment to plug in the power cord may seem like a minor step, but it is crucial for the proper functioning of electronic devices.

8. Turn On The Compressor:

If you want to get your air conditioning unit up and running, you first need to turn on the compressor. This is an essential component of any air conditioning system, as it pumps the refrigerant through the system and allows it to cool the air.

To turn on the compressor, you’ll need to locate the control panel on your unit. This may be a physical switch or a digital display, depending on the model. Once you’ve found the control panel, look for the button or switch labelled “compressor” or “on/off.” Press this button or switch to turn on the compressor.

You should hear a faint humming or buzzing sound as the unit starts. If you don’t hear any noise or the compressor turns off immediately after starting, the unit may have a problem. In this case, you should consult the manufacturer’s instructions or contact a professional HVAC technician for assistance.

9. Monitor Pressure Levels:

Monitoring pressure levels is essential in various industries, including manufacturing, construction, and healthcare. In manufacturing, monitoring pressure levels ensures that production processes run smoothly and efficiently. Any fluctuations in pressure levels can result in defects, which can lead to significant losses for the company.

Similarly, in construction, monitoring pressure levels is crucial in ensuring the safety of workers and the public. Properly maintained machinery and equipment with appropriate pressure levels can prevent accidents and injuries.

In healthcare, monitoring pressure levels is fundamental in diagnosing and treating various medical conditions. Blood pressure, for example, is a critical indicator of heart health and can help doctors identify potential risks for heart disease.

Accurate and consistent monitoring of pressure levels can help doctors make informed decisions about treatment options and improve patient outcomes. In all industries, monitoring pressure levels is vital to maintaining safety, efficiency, and quality. Regular inspections, maintenance, and calibration of equipment can help ensure that pressure levels are consistent and within safe ranges.

10. Turn Off And Drain:

Before leaving for an extended vacation, it’s important to remember to turn off and drain certain appliances and fixtures in your home. This helps save energy and prevents potential water damage or accidents while you’re away.

Make sure to turn off and unplug all electronics, such as your television, computer, and stereo, to avoid wasting energy and risking a fire. Turn off the main water supply valve and drain the pipes to prevent any water from freezing and causing damage.

Remember to turn off and drain your hot water heater to prevent any potential leaks or malfunctions. Lastly, if you have a swimming pool or hot tub, make sure to turn off and drain these as well to avoid any safety hazards. Taking the time to turn off and drain these appliances and fixtures can provide peace of mind while you’re away and save you from potential headaches and expenses in the future.

Conclusion

Setting up your air compressor can seem like a daunting task, but by following the step-by-step guidelines outlined above, you will be well on know how to set up your air compressor. Ensuring that you set up your compressor correctly and safely not only ensures optimal performance but also increases the longevity of your equipment.

As with any machinery, it is important always to follow the manufacturer’s instructions and to prioritize safety in all aspects of the setup process. With these guidelines in mind, you will have the necessary knowledge to set up your air compressor effectively and efficiently.

FAQs

1.What Are The Basic Requirements For Setting Up An Air Compressor?

Ans: You will need a stable surface, access to an electrical outlet or a power source, and a suitable space for the compressor and its accessories.

2.What Type Of Electrical Connection Do I Need For My Air Compressor?

Ans: Check the manufacturer’s specifications for your compressor’s voltage and amperage requirements. Ensure the electrical outlet or power source matches those requirements.

3.How Do I Connect The Air Compressor To The Power Source?

Ans: Use the appropriate power cord and plug it securely into a grounded electrical outlet or connect it to a suitable power supply following the manufacturer’s instructions.

4.How Do I Set The Pressure On The Air Compressor?

Ans: Adjust the pressure using the compressor’s built-in pressure regulator. Consult the user manual for specific instructions on adjusting the pressure to match your desired application.

5.How Often Should I Perform Maintenance On My Air Compressor?

Ans: Regular maintenance is crucial for optimal performance. Follow the manufacturer’s recommended maintenance schedule, which typically includes tasks like oil changes, filter replacements, and inspections.